Trying to stay ahead of slab bundle drayage challenges can seem impossible for shippers. From ensuring damage prevention, specialized handling, regulatory compliance, and minimizing costly delays, transporting stone presents difficulties that must be managed proactively.

If you’re a shipper handling stone material, Heavy Weight Transport is your resource to secure proper drayage expertise, equipment, safety procedures, and best-in-class warehousing.

Tackling Top Slab Bundle Challenges

Finding a highly specialized, end-to-end transport and logistics solution for moving heavy, fragile stone slab bundles between ports, warehouses, and final destinations can test even the best shippers. Heavy Weight’s close associations with the National Stone Institute (NSI) and the Ceramic Tile Distributors Association (CTDA) ensure we solve your daily challenges.

Challenge 1: Securing Trusted Slab Bundle Drayage

Solution: Tap into Heavy Weight’s reliable, comprehensive slab bundle drayage

Heavy Weight’s proven track record as a bonded carrier of heavy haul and standard weight transportation goes beyond basic cargo movement. We cover every state and challenge involved in safely transporting slab bundles through the drayage leg of the supply chain, including:

- Integrated Permitting and Compliance: Inspection, management, and timely acquisition of all required overweight permits at the state and local levels

- Port and Last-Mile Coordination: Real-time scheduling, port terminal appointment management, and on-site support to reduce congestion delays.

- Real-Time Visibility: We keep you updated on your slabs with our 24/7 shipment tracking portal.

- Custom Solutions: Heavy Weight operates industry-leading slab drayage service through specialized equipment and expert drivers for granite, tile, and marble — with the ability to customize services for your complex logistics needs through an in-depth understanding of the unique risks and requirements for slab movement and unloading.

- Specialized Asset Fleet, Equipment, and Handling: Heavy Weight’s specialized fleet of over 1,000 chassis, consisting of 20-foot, 40-foot, and special tri-axle chassis, helps overcome periods of high import volumes or tariff-driven surges that can strain the supply of chassis and specialized trailers needed to move containers or slab bundles efficiently.

“The customer service and responsiveness of working directly with Heavy Weight, as opposed to through a freight forwarder, is the top reason I would recommend them. From excellent communication and on-time delivery of containers, their service always meets my level of expectation.” — Evan Nussbaum, Co-Founder, Stone Project

Challenge 2: Ensuring Safety for Slab Bundle Management

Solution: Feel Secure with Heavy Weight’s “Safety First” Culture

Safety is the cardinal rule Heavy Weight operates by daily — and this couldn’t be more important for transporting, unloading, storing, and handling slab bundles. Heavy Weight goes above and beyond industry safety standards through:

- Packing, Restraint, and Securement: All stone slab bundles are tightly wrapped, strapped, and stabilized inside containers to prevent load shifting in transit.

- Wooden supports or bracing are left in place until mechanical handling tools are ready and workers are in safe positions

- Racks and A-frames are inspected for capacity and integrity before loading or unloading begins.

- Mechanical Handling and Equipment Controls: Using mechanical devices (forklifts with appropriate attachments, cranes, slab lifters) avoids manual lifting. Drivers and crew receive specialized training on safe operation and inspection of equipment before each use.

- Standard Operating Procedures and Training: Documented Standard Operating Procedures (SOPs) and safety training for each stage: securing, lifting, unloading, and storing slabs are enforced. Access to the “fall shadow” is restricted.

- Compliance With Regulatory Guidelines: Operations comply with OSHA, DOT, and industry safety standards for cargo securement, equipment use, and workplace practices.

Challenge 3: Securing Optimal Warehousing

Solution: Heavy Weight’s Tailored Long Beach, CA Facilities

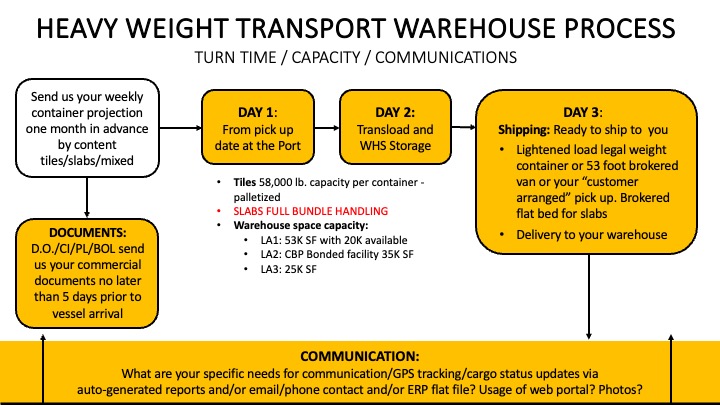

Customized for the busiest port in the United States for containerized imports, including stone and tile slab bundles, Heavy Weight’s warehouses located near the ports of Los Angeles and Long Beach, California, support a seamless supply chain through:

- Three locations inside the Overweight Container Corridor. Heavy Weight warehousing is the only resource within the corridor that can handle bundled slabs and slab handling; also, ABC licensed for spirits, flat-bed loading.

- One bonded facility, offering approximately 35,000 square feet of storage, allowing shippers to store imported goods for a period of up to five years.

- Cleanliness promise: Experienced stone and tile professionals thoroughly inspect each container for insects and compromised woos.

- FDA-registered food-grade warehouse

- 24/7 surveillance, including alarm systems and periodic security checks.

Ready to get comprehensive slab bundle service?

Click here to schedule a free consultation with our experts. We can help you navigate today’s complex slab bundle shipping with confidence — and better cash flow